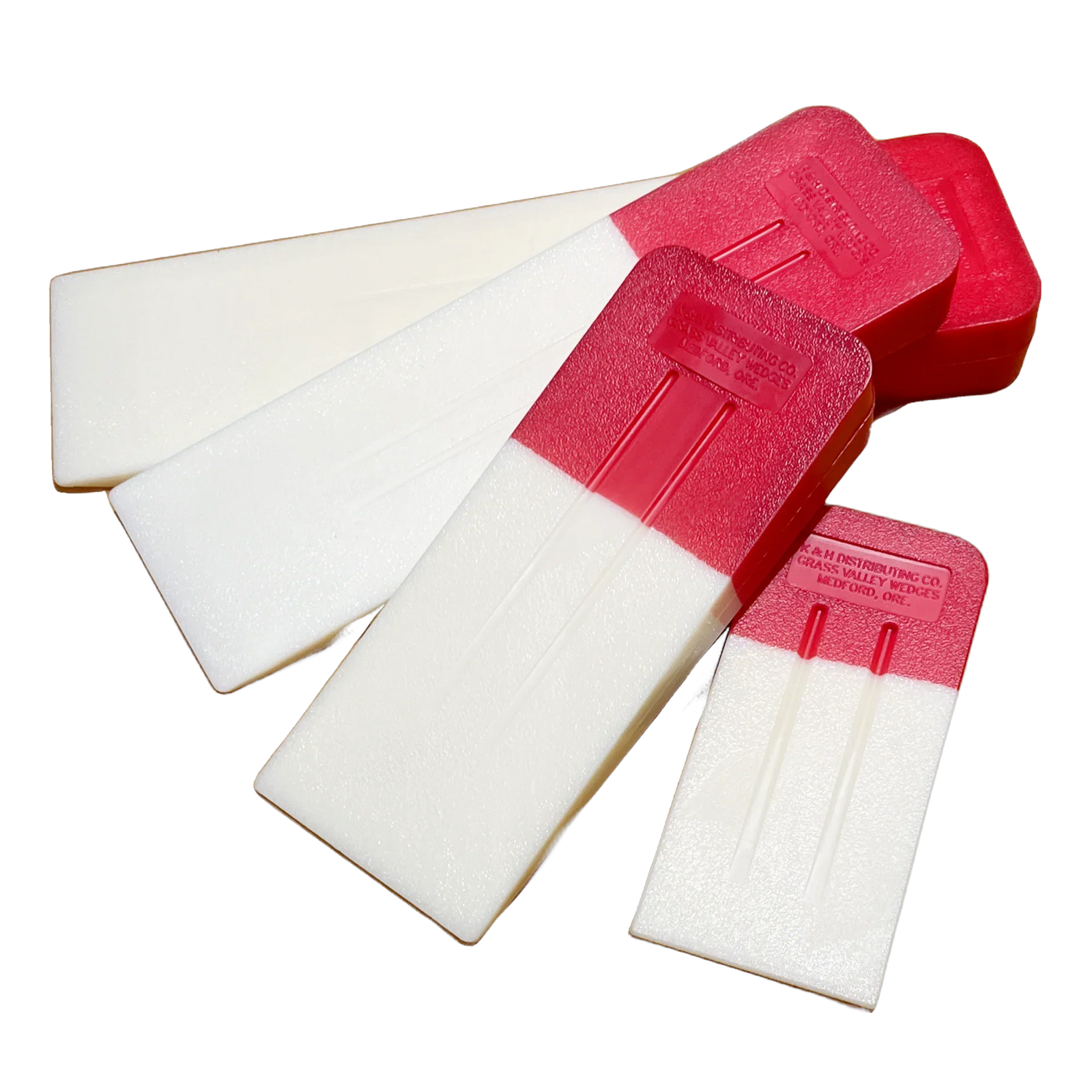

Understanding the K & H "Red Head" Wedges

Introduced in 1962, K & H’s "Red Head" Wedges have become iconic tools in various industries, recognizable by their distinctive red tops. Here’s what makes these wedges standout:

- Durability and Safety: Made from non-sparking, durable ABS plastic, these wedges are both sturdy and safe, especially around potential fire hazards, common in logging and construction sites.

- Lightweight Construction: The material is not only tough but also lightweight, reducing strain for operators while providing reliable lifting and splitting strength.

- Anti-Slip Texture: Textured surfaces reduce the risk of slipping during use, enhancing control and safety.

- Versatility: K & H "Red Head" Wedges are used across small to large timber industries, as well as in automotive, bridge construction, and more.

Each wedge size is designed with specific applications in mind:

- 5 ½" Wedge: Best for smaller timber and versatile enough for use in automotive and construction settings.

- 7 ½" Wedge: Suited to medium-sized timber felling and firewood preparation.

- 10" Wedge: A favorite for heavy-duty felling tasks and industrial applications.

- 12" Wedge: The largest in the lineup, favored by timber fallers and bridge inspectors for its unparalleled lifting capability.

Why Wedging is Essential in Felling Trees

Felling trees is a complex process that relies on precision, skill, and the right tools. Wedging plays a crucial role for several reasons:

-

Controlled Directional Fall:

- Wedges help direct a tree’s fall, which is vital for safety and efficiency. A well-placed wedge can guide a tree to fall in the intended direction, minimizing risks to surrounding structures or people.

-

Preventing Backfall:

- As a tree begins to fall, the risk of it "sitting back" and reversing the fall direction increases, which can be hazardous. A wedge acts as a physical stop, holding the tree in place and preventing backfall, even in challenging weather conditions or uneven terrain.

-

Increasing Cutting Efficiency:

- Wedging helps open the tree’s cut, making it easier to continue sawing without pinching the chainsaw. This is especially important when dealing with large or dense timber that can press on the saw blade.

-

Enhanced Safety for the Feller:

- The wedge serves as an anchor point, allowing the feller to operate from a safer position, reducing the risk of the tree or branches coming back toward the operator.

-

Efficient Timber Splitting:

- Besides directional control, wedges are used to split timber effectively. The material and structure of K & H wedges make them suitable for high-impact applications, such as splitting dense timber.

Choosing the Right K & H Wedge for the Job

The size of the tree and the task at hand dictate the ideal wedge size. Here’s a breakdown of which wedge might be best for specific scenarios:

- For Small Timber and Firewood Prep: A 5 ½" wedge is generally sufficient.

- Medium Timber: Opt for a 7 ½" wedge, which provides enough lift without excessive weight.

- Heavy Timber and Industrial Use: The 10" wedge is preferred for its combination of size and lift capacity.

- For Large Scale Projects and Timber Felling: The 12" wedge is perfect for the largest timber or construction applications.

Conclusion: The K & H "Red Head" Wedge Advantage

The K & H "Red Head" Wedges are more than just felling tools; they are precision instruments designed to enhance safety, efficiency, and control in felling and timber work. Trusted by professionals for over half a century, these wedges reflect a blend of durability, ergonomic design, and practicality, making them indispensable tools in any feller’s kit. Whether in the forest, at a construction site, or in industrial applications, K & H wedges continue to set a standard for excellence.

Leave a comment (all fields required)